Corrosion for all chemical equipment is like a flood of beasts in general terrible thing, once the equipment is damaged, often lead to industrial accidents or disasters, in the selection of engineering plastic pumps must pay attention to the selection of corrosion-resistant materials, fluorine lined pumps can effectively resist sulfuric acid, non-metallic materials are not easy to suffer the destruction of hydrochloric acid, fluorine plastic alloys, as well as stainless steel industrial plastic pumps is not easy to corrode in the nitric acid conditions. Corrosion.

All engineering plastic pumps are in pursuit of zero leakage of the perfect delivery results, the current magnetic pump to get thousands of attention for precisely the same reason, the pump body in most cases using gaskets and seals to static sealing, mechanical sealing is the most important form of dynamic sealing, to the sealing cavity into the isolation fluid can be made to be tightly closed, the sealing material of the engineering plastics pumps are mainly fluoroelastomer.

If the viscosity of the engineering plastics pump rises, it will lead to head and flow are continuing to decline, power over the established range and make the efficiency of a drop, the parameters of the transmission of viscous media can not be compared with the transmission of clear water when the qualified engineering plastics pumps will inevitably take into account the conditions of different viscous liquids transport, such as the viscosity of the slurry liquids are suitable for use of the mortar pump transport.

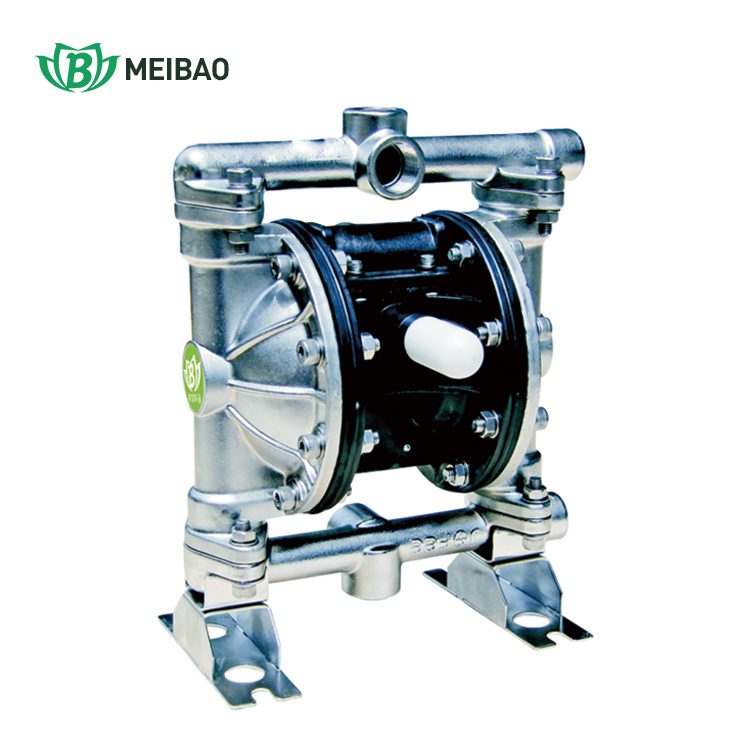

The engineering plastics diaphragm pump has a reliable operating performance. It adopts the diaphragm driving principle, which makes the diaphragm move back and forth by air or liquid pressure to achieve the transport of liquid. Compared with other types of pumps, the engineered plastic diaphragm pump has a simple structure and a small number of moving parts, reducing the possibility of failure. It eliminates the need for shaft seals and sealing devices, avoiding leakage problems, and is capable of handling highly viscous liquids, media containing solid particles, and volatile liquids. In addition, the engineered plastic diaphragm pump is self-priming and dry-running, enabling it to operate in dry conditions without damage.