The electroplating industry, as an important part of modern industry, brings the challenge of wastewater treatment while promoting economic development. Especially in electroplating parks like Tongling in Anhui Province, wastewater treatment and discharge has become a top priority for environmental protection. This article will introduce you to the electroplating park wastewater treatment process, and focus on why in the acid and alkali wastewater transportation, Mabel can be idle self-priming pumps become a good choice.

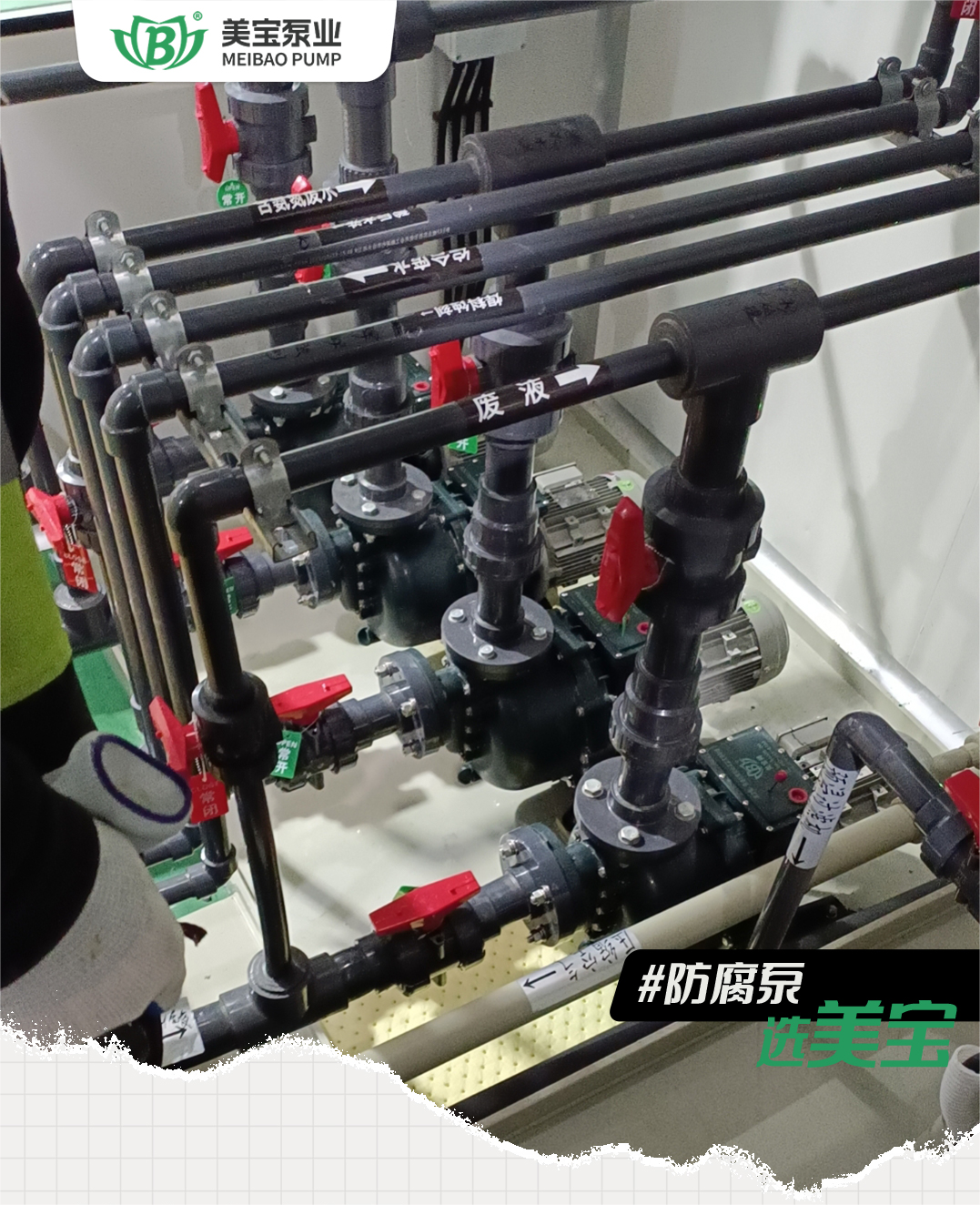

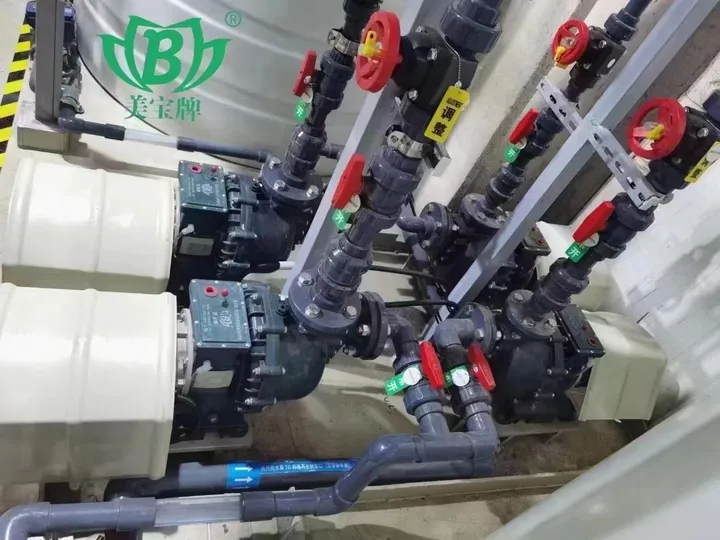

Electroplating park wastewater treatment process mainly includes wastewater collection, pretreatment, deep treatment and discharge and other links. Among them, wastewater transportation is a key step connecting each link, which has a direct impact on the effect of wastewater treatment. Acid and alkali wastewater as one of the main types of electroplating wastewater, its conveying equipment needs to have acid and alkali resistance, corrosion resistance to ensure that wastewater can be safely and efficiently transported to the treatment equipment.

In many wastewater transportation equipment, Mabel can idle self-priming pump with its unique advantages, become the ideal choice for acid and alkali wastewater transportation. The following are the features and functions of idling self-priming pumps in acid and alkali wastewater transportation:

Idle without water, strong adaptability

Mabel idling self-priming pump has the feature of idling without water, which can be automatically adjusted according to the size of the cooling tank. In the process of wastewater treatment, even if there is a short interruption in the wastewater supply, the pump can continue to run, avoiding wastewater leakage and environmental pollution due to pump stoppage. This adaptable feature makes the idling self-priming pumps widely used in waste water treatment in electroplating parks.

Acid and alkali resistance, corrosion resistance

Mabel idling self-priming pumps are manufactured with preferably imported A-grade raw materials, such as FRPP and PVDF, which have excellent acid and alkali resistance and corrosion resistance. When conveying acid and alkali wastewater, the pump body is able to resist chemical corrosion and ensure long-term stable operation. This strong corrosion resistance makes the idle self-priming pump highly reliable in electroplating wastewater treatment.

Strong self-priming force and high efficiency

Mabel's idle self-priming pumps are designed with a particularly strong self-priming force of up to 20 ft. This design allows the pump to draw wastewater into the pump body quickly after startup, reducing startup time and energy consumption. At the same time, the high efficiency of the pump makes the wastewater conveyance faster and improves the efficiency of wastewater treatment.

Compact and easy to install

The Mabel Idle Self-priming Pump adopts a one-piece molding design, with the back cover and feet, self-priming drum and main body all molded in one piece. This compact structure reduces leakage points at the joints and improves the strength and life of the pump. At the same time, the one-piece molding design also makes the pump easier to install, reducing installation time and cost.

Unique impeller design for solid performance

The impeller of the Mabel Idle Self-priming Pump is manufactured using one-piece injection molding technology with no welded joints for high efficiency and solid performance. This design allows the pump to maintain a stable performance output when transferring wastewater and avoids pump failure due to impeller damage.

High quality materials, safe and reliable

The Mabel Idle Self-priming Pump is manufactured with high quality materials, such as Dongming brand SUS316 screws and Taiwan TECO motors. These high quality materials ensure the safety and reliability of the pump, reducing the failure rate and maintenance costs.

To summarize, Mabel can idle self-priming pumps play an important role in electroplating park wastewater treatment by virtue of its no water can idle, acid and alkali resistance, corrosion resistance, strong self-priming force, compact structure, unique impeller design and high quality materials and so on. Choosing Mabel can be idle self-priming pump as acid and alkali wastewater transfer equipment can not only improve the efficiency and quality of wastewater treatment but also reduce operating costs and maintenance costs. Therefore, it is wise to choose Mepco idle self-priming pumps in electroplating park wastewater treatment projects.