Concentrated nitric acid, as an important chemical raw material, is widely used in several industrial fields. However, its strong oxidizing and corrosive properties make the conveying of concentrated nitric acid a technical challenge. In the field of environmental protection, the requirements for the transportation of concentrated nitric acid are particularly stringent, requiring the selection of corrosion-resistant, safe and reliable pump products. Mabel pump industry with its deep technical accumulation and professional R & D strength, for the environmental protection field of concentrated nitric acid conveying provides efficient and reliable solutions.

Concentrated nitric acid is characterized by high concentration, strong oxidation and corrosiveness. This water quality characteristic requires the pump not only to have good corrosion resistance, but also to be able to cope with the challenge of strong oxidizing. In addition, concentrated nitric acid also needs to maintain its purity and stability in the process of conveying, to avoid reacting with the conveying equipment or producing pollution.

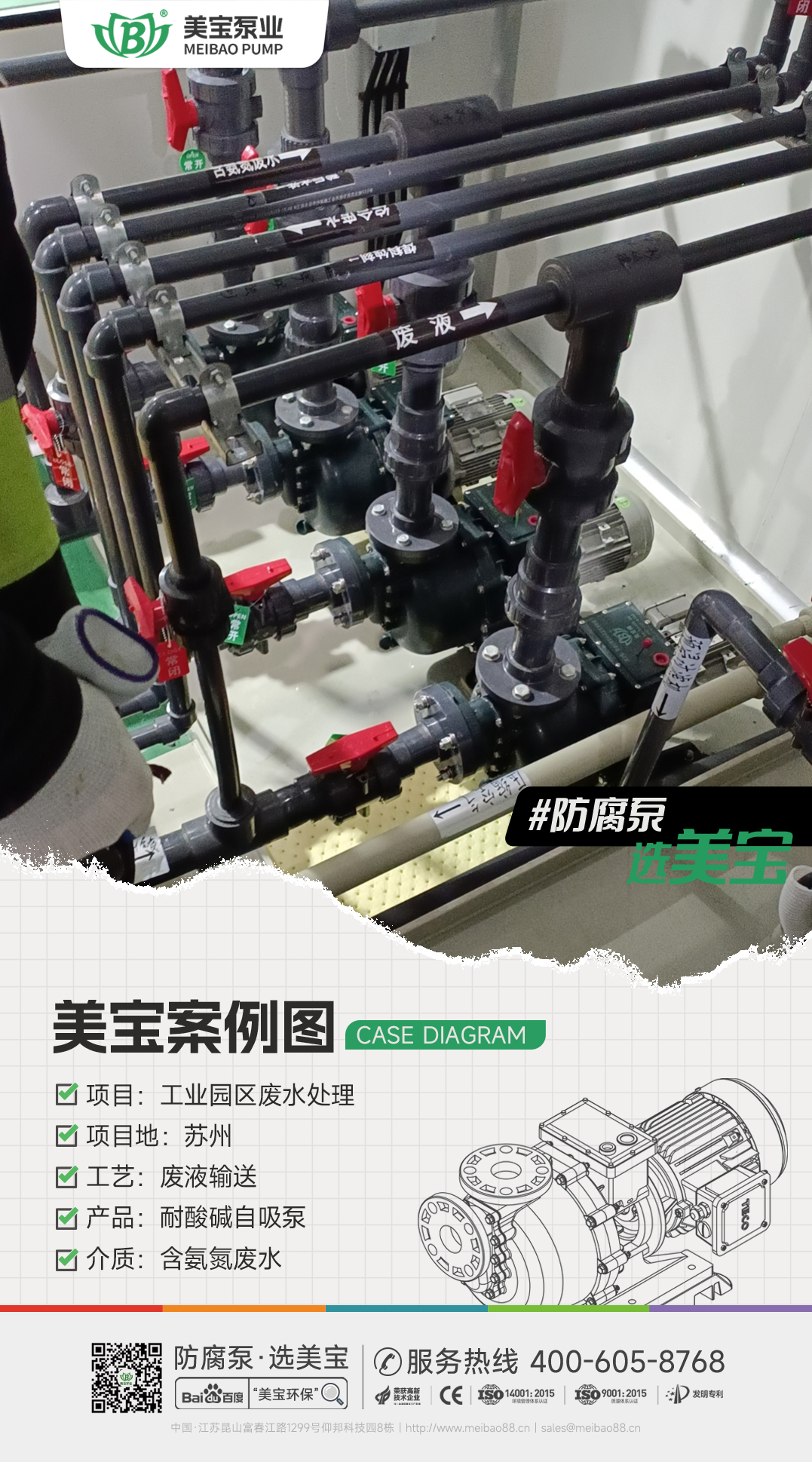

In the field of environmental protection, concentrated nitric acid is mainly used in waste gas treatment, waste water treatment and other processes. For example, in waste gas treatment, concentrated nitric acid is used as an absorbent to react with harmful gases and realize the purification and discharge of waste gas. In wastewater treatment, concentrated nitric acid is used to adjust the pH value of wastewater and promote the precipitation and separation of pollutants in wastewater. These processes put forward high requirements for the delivery pump of concentrated nitric acid.

For these characteristics and application scenarios of concentrated nitric acid, Mabel Pumps has developed specialized corrosion-resistant pumps. These pumps are made of highly corrosion-resistant materials, such as special alloys and polymer materials, which can effectively resist the corrosion and oxidation of concentrated nitric acid. Meanwhile, the design of the pumps also takes into full consideration the purity and stability requirements of concentrated nitric acid, and ensures that the concentrated nitric acid will not be contaminated or leakage during the conveying process by optimizing the flow channel structure and sealing performance.

In addition, Mabel Pump also focuses on the development of product intelligence and automation. Through the introduction of advanced control technology and sensor technology, Mabel Pump's concentrated nitric acid transfer pumps can realize remote monitoring and intelligent adjustment, which improves the operation efficiency and stability of the equipment. This intelligent and automated design not only reduces the operation difficulty and labor cost, but also improves the reliability and safety of the equipment.

In actual cases, Mabel Pump's concentrated nitric acid transfer pumps have been widely used and recognized. For example, in the waste gas treatment project of a large chemical enterprise, Mabel Pump's corrosion-resistant pump successfully solved the corrosion and leakage problems in the process of concentrated nitric acid conveying and ensured the stable operation of the waste gas treatment process. At the same time, the efficient and stable operation of the pump also saves a lot of maintenance costs and labor costs for the enterprise.

To summarize, Mabel pump industry with its professional technical strength and rich experience in the industry, for the environmental protection field of concentrated nitric acid conveying provides an efficient and reliable solution. In the future, Mabel Pump will continue to devote itself to technological innovation and product upgrading, contributing more strength to the development of environmental protection.