Etching solution, a kind of special solution composed of chemical corrosive agent and other additives, its water quality is mainly characterized by strong corrosiveness and specific chemical reactivity. In the field of precision manufacturing and surface treatment, the application of etching solution is crucial. This special chemical solution with its strong corrosiveness and specific chemical reactivity, for microelectronics, glass manufacturing, precision instruments and many other industries has brought revolutionary progress. However, the process of transferring etching solutions is a technical challenge that requires high-performance, corrosion-resistant pumps to ensure stable, reliable delivery.

The water quality characteristics of etching fluids dictate that the pumps must be extremely corrosion resistant. This kind of liquid usually contains strong acid or alkali components, and has a strong corrosive effect on ordinary metal materials. Therefore, the traditional metal pump is difficult to meet the needs of etching liquid transportation. In addition, the etching solution needs to maintain a stable temperature and pressure during transportation to ensure that the nature of the liquid does not change, which puts forward higher requirements on the performance of the pump.

In view of the special nature of etching liquid, Mabel pump industry has launched a specially designed transfer pump for etching liquid. Mabel pump adopts high-performance engineering plastics materials, with excellent corrosion resistance, can be stable for a long time to transport etching solution without corrosion. At the same time, Mabel pump industry in the design process fully considered the liquid temperature and pressure control needs, to ensure that the liquid in the transfer process to maintain a stable nature.

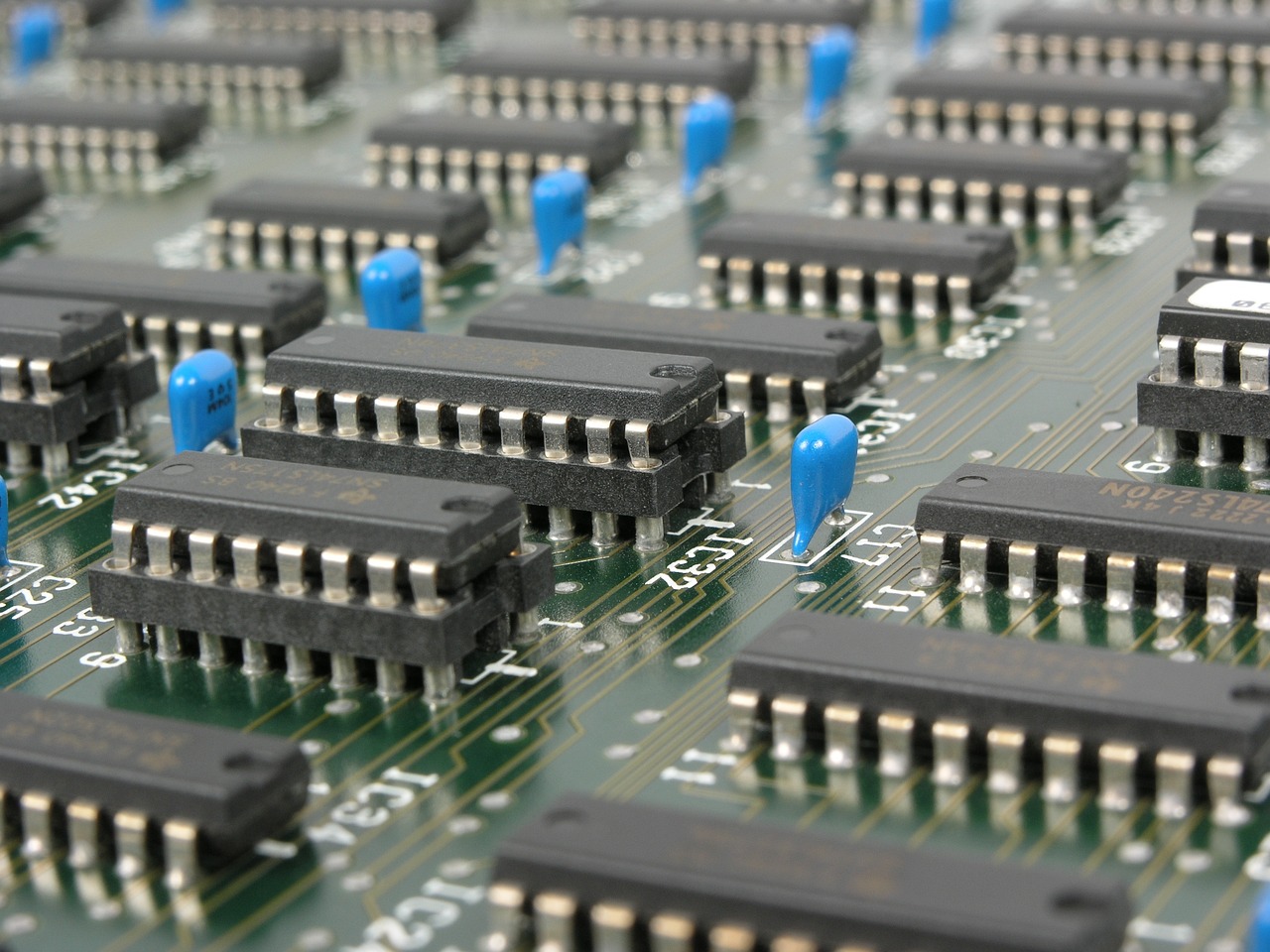

Etching liquid is widely used in many fields. In the microelectronics industry, etching solutions are used in the manufacture of integrated circuits and printed circuit boards by removing unwanted metal layers to form the lines and spacing of circuits. In the glass manufacturing industry, etching solutions are used to create unique patterns and textures on glass surfaces, enhancing the decorative and artistic aspects of products. In addition, etching fluids also play an important role in precision instrument manufacturing and machining.

Microelectronics industry case: a well-known microelectronics manufacturing enterprises, in the production process of integrated circuits, a large number of etching solution. In the past, they have been facing problems such as unstable liquid transportation and serious corrosion of the pump body. Since the adoption of Mabel Pump's etching liquid transfer pump, these problems have been completely solved. Mabel's pump not only has excellent corrosion resistance, but also can stably and efficiently transport the liquid to the production line, greatly improving production efficiency.

Glass manufacturing industry case: a high-end glass manufacturing enterprises, in the glass surface etching process requires the use of special etching liquid. The transfer pump they used before was often leaking and clogging, which seriously affected the production progress. After the introduction of Mabel Pump's etching solution transfer pump, these problems have been significantly improved. Mabel Pump's transfer pump can not only effectively avoid leakage and clogging, but also accurately control the flow and pressure of the liquid to ensure the uniformity and consistency of the etching effect.

For these different areas of application needs, Mabel pump industry provides a variety of models of etching liquid transfer pump. Whether you need high flow rate delivery or high precision control, Mabel pumps can meet the needs of customers. At the same time, Mabel Pump also provides customized services for customers, according to the specific composition of the liquid and process requirements, to create an exclusive transfer pump solutions for customers.

With a professional technical team and rich industry experience, Mabel Pump has become a leader in the field of etching liquid transfer pumps. We understand the importance of etching solution in industrial production, and we also understand that our customers have strict requirements on the performance of transfer pumps. Therefore, we are committed to providing customers with efficient, stable and reliable etching liquid transfer pump products and services. Choose Mabel Pumps to make your etching process smoother and more efficient!