People who understand the electroplating industry know that the electroplating field production and discharge of wastewater is very complex, then so much wastewater solution should be how to choose the right transfer pump, what transfer pump can be used to solve the problem of electroplating wastewater. Today we will share with you which organic wastewater transfer pumps can be used for electroplating wastewater treatment.

Electroplating industry produces different wastewater according to different processes, the wastewater discharged contains chromium, nickel, cyanide, acid, alkali and other solutions. Among them, heavy metal wastewater is a potentially hazardous wastewater category in the electroplating industry.

(1) Nickel plating: nickel is a carcinogenic heavy metal electricity, which is processed second only to galvanising. However, crystallisation will occur during transfer and, depending on the site, a vertical transfer pump that can be idled should be used.

(2) acid and alkali liquids: commonly used acid and alkali FRPP material and PVDF material, PVDF high temperature resistance of more than 100 degrees, and resistance to high concentrations of acid and alkali. Temperature of 70 degrees on the use of FRPP.

(3) Chromium plating: there are trivalent chromium and hexavalent chromium, due to the different effects of acidity, trivalent with FRPP material acid and alkali resistant pumps can be used, hexavalent with PVDF material resistant to strong acidic wastewater transfer pumps.

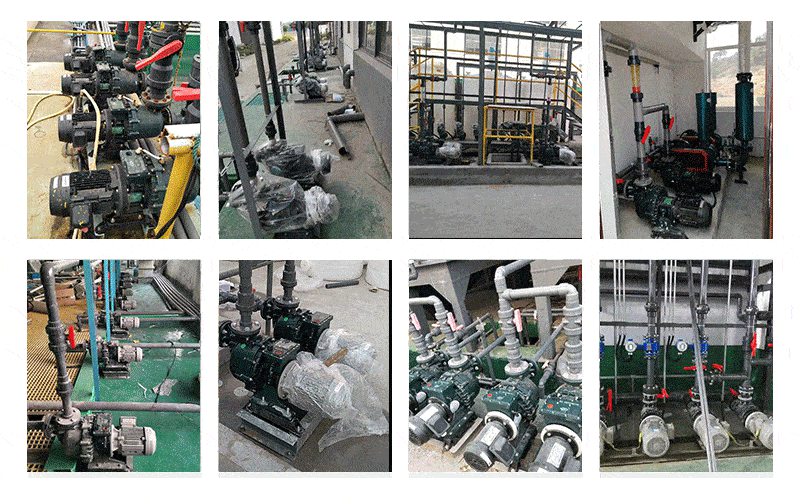

With the improvement of people's living standard, the appearance of cars, tables and chairs also have a high pursuit. In the electroplating industry want to achieve such an effect, there is no shortage of high-precision filtration electroplating filter. Mabel specialises in the production of acid and alkali resistant pumps and plating filters, all-in-one, high-precision filtration and acid and alkali resistance, and to provide supporting the use of acid and alkali resistant pump solutions. For more information about self-priming pumps, please feel free to contact us.